Description

Damasko DC57 (SI Upgrade + SI Dial)

The Damasko DC57 (SI Upgrade + SI Dial) merges classical chronograph heritage with cutting-edge material technology. This model stays true to the iconic Valjoux 7750 design, enhanced with a silicon escape wheel and a full-lume dial surface, offering unmatched visibility and performance in a refined 40mm case.

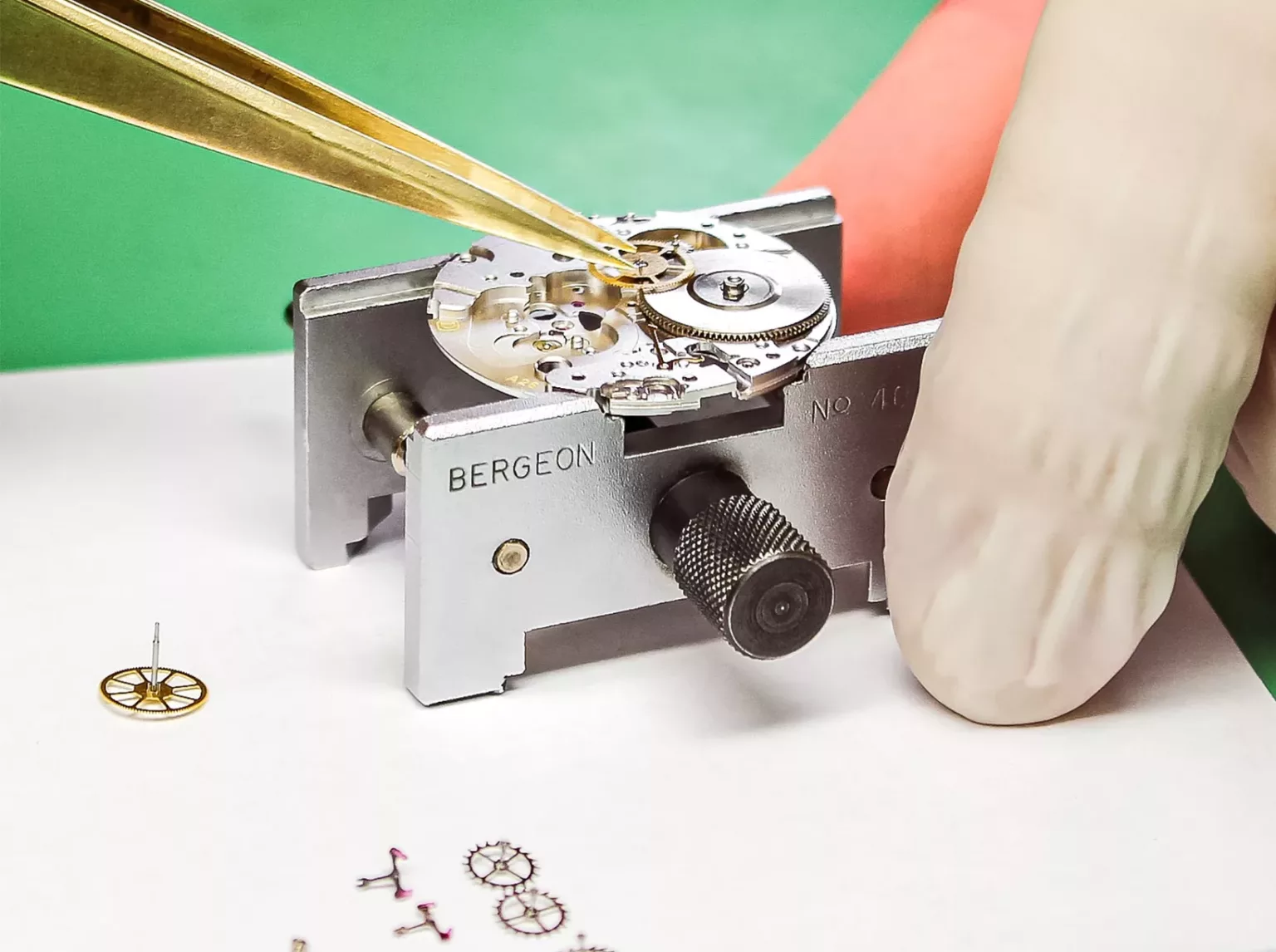

As part of the DC5X series, the DC57 is powered by the Swiss Valjoux 7750—a movement renowned for its reliability and accuracy. Featuring a 12-hour counter, 30-minute counter, and central 60-second counter, it maintains the traditional tri-compax layout while offering enhanced functionality through silicon component upgrades.

The case is crafted from DAMASKO’s ice-hardened, nickel-free stainless steel, reaching a hardness rating of up to 64 HRC / 800 Vickers—four times tougher than conventional stainless steel. This proprietary steel is used throughout the case, crown, bezel, and pushers.

The movement is regulated and tested by DAMASKO for precision and durability. It includes a silicon escape wheel as standard, with an optional silicon hairspring available. Shock-resistant to DIN 8308, the movement also offers a 48-hour power reserve.

The dial surface is completely coated with Luminova C1 Grade X1 white luminous material, delivering exceptional low-light readability. Matte black sword hands, indices, and a triangle at 12 o’clock provide contrast. A black “Si” imprint at 8 o’clock and an additional 60-second ring at 9 o’clock are subtle nods to the watch’s advanced internals. The day/date window is discreetly positioned below the 3 o’clock axis and colour-matched to the dial.

The watch is sealed using triple-protection Viton gaskets, ensuring chemical resistance and long-term performance. It features a screw-down case back, water resistance to 10 bar (100 metres), and curved lugs for ergonomic comfort. A flat sapphire crystal with anti-reflective coating ensures clarity in all lighting conditions.

The patented DAMASKO crown and pusher system allows safe underwater use, with a disengaged setting stem when secured to protect the movement from shocks. The integrated lubricant cell maintains long-term smooth functionality.

To ensure precision in the harshest conditions, the DC57 includes an anti-magnetic cage that shields the movement up to 80,000 A/m (100 mT)—a rare and valuable feature in modern mechanical watches.

The watch is supplied with a comfortable black leather strap with black-white double stitching and a bead-blasted signed buckle. A matching ice-hardened steel bracelet is available as an option.

Movement Options: Standard: Élaboré, Optional: TOP version with silicon escape wheel (please contact us to order).

Technical Specifications

- Movement: Valjoux 7750 TOP with silicon escape wheel (optional silicon hairspring)

- Power Reserve: 52 hours

- Functions: Hour, minute, small second, date and weekday (German or English), chronograph with 12-hour, 30-minute, and 60-second counters

- Case: Ice-hardened stainless steel; case back and crown screwed; crown protection with DAMASKO System

- Water Resistance: 10 bar / 100 metres; low pressure resistant; tested to MIL-STD-810

- Crystal: Flat sapphire with anti-reflective coating

- Dial: Fully coated in Luminova C1 white; matte black hands and markers; “Si” imprint at 8 o’clock; 60-second scale at 9 o’clock

- Anti-Magnetic Protection: Up to 80,000 A/m (100 mT)

- Dimensions: 40.00 mm diameter; 13.80 mm height; 20.00 mm lug width; 48.6 mm lug to lug

- Weight: 90 g (without strap)

- Strap Options: Black leather strap with black-white double stitching; optional Ice-Hardened Steel Bracelet

Main MenuMain Menu

Main MenuMain Menu